At Innovare Offsite, we believe quality isn’t something to be checked at the end of a project, it’s something you build in from the very start.

Digital quality management systems play a crucial role in enabling that approach providing visibility, streamlining collaboration, and ensuring that what is designed is precisely what is delivered. Yet, technology alone is not the answer. True transformation comes from how organisations apply these tools, create the right culture, and drive continuous improvement. Software can illuminate opportunities, but it’s leadership, discipline, and commitment to efficiency that turn those insights into measurable outcomes. For us, digital quality management is not just about adopting a system it’s about shaping an environment where innovation and quality go hand in hand.

Artic has become a game-changer in how we manage our workflows. From real-time quality checks to takt-based production scheduling Artic gives us the tools to deliver high-performance offsite Low Carbon Fire Safe products and Low Risk Rapid Build solutions. Its built-in checks mean nothing leaves our factory without passing inspection, while its takt management feature keeps production and site installation in sync. By setting daily targets and visualising progress, it helps create a steady rhythm of work that reduces delays and keeps everything moving smoothly. The real-time dashboards give us visibility of what’s happening across multiple projects and even across different regions, allowing us to spot issues early, benchmark performance, and keep improving. It’s become the digital backbone of how we deliver consistently, efficiently, and with confidence.

One of the biggest changes has come from using Plan Radar. Instead of simply recording snags or repairs, it allows us to verify every element against design standards all the way from manufacturing through to installation on site. With photo signoffs, our teams can capture hands-free data in real time, which is automatically tagged and organised. The AI tools help flag potential issues before they escalate, while the built-in ticketing system means updates are instantly shared across teams in a way that everyone can understand. The result is clearer communication, quicker decision-making, and far less time spent chasing paper trails.

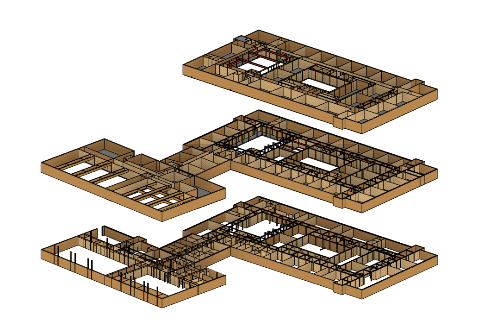

Once the structure is in place, we turn to cloud point surveys for one final assurance. 3D scanning gives us a precise digital replica of the building, which we can compare directly with the original BIM model. Any misalignments, defects, or gaps are instantly visible, so they can be fixed before they cause problems later. These scans also provide objective evidence for sign-off and compliance, ensuring traceability at every stage. Most importantly, they guarantee that what we’ve built performs exactly as designed, preventing issues like energy loss, acoustic problems, or thermal inefficiencies.

Bringing these tools together Plan Radar, Artic, and cloud point surveys has allowed us to create a joined-up way of working where quality is built in from day one. For our clients, that means fewer delays, fewer surprises, and complete confidence in the outcome. Using a digital quality management system transforms quality from a reactive process into a proactive advantage, making offsite manufacturing and construction faster, safer, and more reliable.