Home | Key benefits of SIPs

Key benefits of SIPs

Whatever the complexity, scale or ambition of your project we believe the building system offers the simplest, most reliable and best value solution for Structural Insulated Panels or SIP construction.

Structural Insulated Panels offer significant advantages in a world where construction schedules are becoming shorter, building performance criteria becoming more challenging, and the need for innovative solutions to ambitious construction targets and skilled labour shortages are paramount.

Offsite construction must meet the same regulations and standards of traditional construction, but reduces waste and improves sustainability thanks to the more efficient factory based production process, compared to onsite labour and materials and reduced whole-life cost. The more precise and flexible factory production environment enables more creativity without compromising performance and cost savings.

The ability of modular, insulated panel methods of construction to lower risk and add value means if can often exceed the performance of traditional in terms of both the project delivery and end product.

Reduce Risk

- Predictability: build as design offsite production means much greater programme delivery predictability

- Safety: reduced time and labour on-site as well as less processes on site as well as reducing the need to work at height as more can be done from the ground with an installation

- Standardisation: standard products and standard pricing helps simplify the process

- Variability: flexibility and speed of design and manufacturing process enables variability at a cost effective level

- Disruption: deliver and install much more reliable and consistent than material and labour in-site

- Disturbance: reduced time and labour onsite reduces inconvenience

- Future Flexibility: modular format ensures future-proofing can be built in to accommodate usage changes over time

- Management: no warranty, insurance or maintenance requirements

Add Value

- Speed: helps reduce time across each phase with short design lead in, reduction in programme time with a quickly established watertight envelope and scaffold free assembly and reduced snagging.

- Affordability: significant savings can be achieved with a reduction in programme time through the greater speed of installation over traditional construction as well as reduced M&E costs.

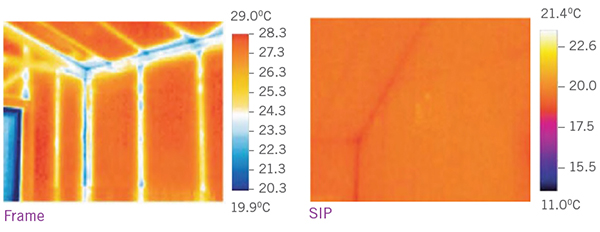

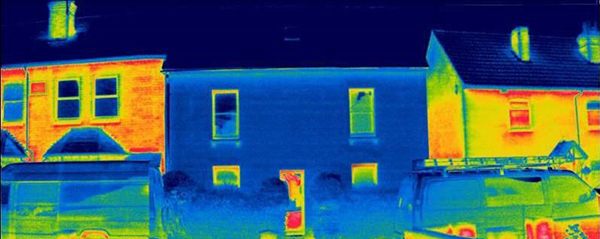

- Performance: With U-values as low as 0.09 W/m²K, the inherent excellent insulating properties and superior air tightness the energy consumption and running costs of a building and enable a lower specification heating system. Improved thermal bridging also reduces heat loss.

- Precision: manufacturing standard tolerances ensure a precise fit and faster installation

- Sustainability: sustainable resourcing of materials and intelligent inventory system, carbon reduction production processes and reduced whole-life maintenance all contribute to a more sustainable method of construction.

- Defects: structural integrity and lightness of SIPs eliminates settlement reducing time required for snagging, allowing occupants to take up residence sooner.

Offsite construction is highly adaptable. s and be used for walls, floors and roofs and they can form all or part of a building.

Structural insulated panels contribute positively to the environment by helping to lower CO2 levels. s have significantly lower embodied energy than traditional construction materials such as steel, concrete and masonry.

Sequestered carbon is carbon safely trapped within timber building materials that would otherwise be in the form of atmospheric CO2 . Buildings made out of SIPs become an effective form of carbon storage. The carbon is locked up until the building is demolished and the carbon released. The long lifespan of our buildings make them ideal for this type of carbon offset and storage in a way which can be more easily observed and measured.

Technical Information

Superior energy efficiency

With U-values as low as 0.09 W/m²K, the inherent excellent insulating properties and superior air tightness of a finished SIP structure reduce the energy consumption and running costs of a building. Often it is possible to specify a lower specification heating system and reduce the cost and complexity of the HVAC installation.

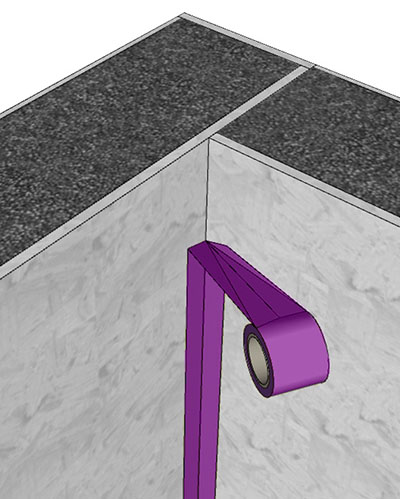

Air Tightness

Few methods of build can match the air permeability levels achievable with large format SIP panels. The only ones of its type manufactured in in the UK, Innovaré Offsite’s panels can measure up to almost 6 x 3 metres. Fewer structural joints and connections combined with the exacting panel tolerances of ±2mm make s one of the easier ways to achieve levels of air leakage as low as 0.6 m3/m2hr@ 50 pascals. Taping the joints allows structures to achieve Passivhaus standards.

Minimal cold bridging

The Y-value measures the total heat loss expected from thermal bridging in all of the junctions of the building. The Innovaré Offsite system has a typical Y-value of 0.025 W/m²K exceeding the accredited and enhanced construction details values of 0.08 and 0.04 W/m²K respectively.